Calibration is a procedure that must be performed at regular intervals. It verifies the working condition of the systems & measuring equipment’s. As a part of our focus on end-to-end services, we have initiated to set up a ISO17025 accredited calibration facility, mainly for site calibration of HV test systems. Our primary aim is to provide customers who buy their HV test systems from us, the option to have their test systems calibrated annually and in a cost-effective way.

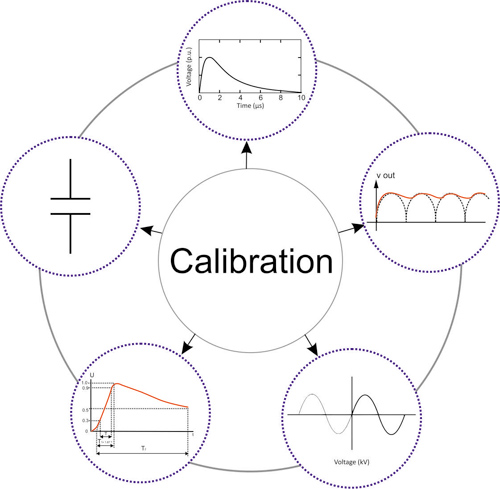

Calibration Capabilities:

- AC High Voltage: Range – up to 500kV for HV test systems up to 2000kV & equipment’s up to 400kV

- DC High Voltage: Range – up to 100kV for HV test systems up to 500kV & equipment’s up to 100kV

- Impulse Voltage: Range – up to 500kV for IVG up to 2000kV for Impulse wave generator & oscilloscope >10ns, 500V

- C & Tan Delta: Range – 10pF to 1uF, 0.000001 to 1, 400kV for standard capacitors up to 1600kV

Why Calibration Matters

- Saves Money: Calibration reduces errors that can get costly in the long run. Who don’t calibrate their systems/ equipment’s will end up with errors that create unusable parts & they will often have to halt and restart processes when inaccuracies are discovered. The longer it takes for those inaccuracies to get noticed, the more costly the mistake will be.

- Improves Safety: Small inaccuracies can have large consequences. Maybe you’re measuring electric voltage/currents, small changes to the numbers can quickly put your staff in danger. Calibration allows you to get reliable numbers for improved safety.

- Gets You Certified: You’ll need calibration to get certified in a lot of industries.

- Keeps Instruments Working Longer: Over time, the accuracy of any measuring system/equipment goes down. When you calibrate your equipment, you set it back to the original standard, so you can keep using it. The equipment that’s giving inaccurate readings probably doesn’t need to be replaced – it just needs calibration.